The first thing that comes to your mind is to use a welder when you want to join two metal pieces together. The second question that may arise in your mind is “Is there any way we can join two metals without using a welder?” or “Is it possible to connect two metals without using a welder at all?”

Well yes. You might think that using a welder is the best method when it comes to welding two metals and in some cases, this is absolutely true. But have you tried to explore the other ways that can help you get the same result as welding?

Here you will get to know about some different methods and techniques which you can use if you don’t want to use a welder at all. Stick to the topic and you might discover some fascinating ways that can make your life a lot easier and help you in the welder-free welding process.

Contents

Can you weld two metals without a welder?

The answer is yes.

Welding requires practice and knowledge. Plus you need to have the equipment and supplies for welding. Here we will be discussing a few methods and techniques to weld two metals without using a welder.

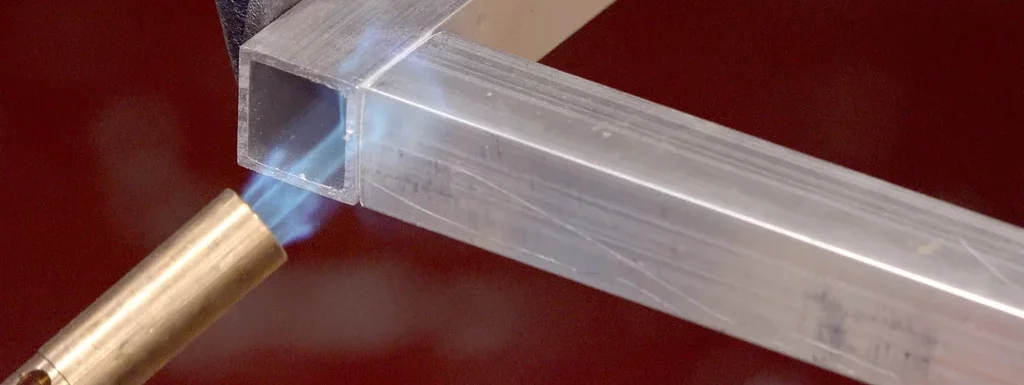

Brazing

If you are looking to weld without a welder, brazing is a pretty simple process that is similar to welding. Because it also involves the use of heat to connect the two pieces of metal. Also, it is less costly than welding.

Well, the important thing to remember about brazing is to make sure that the filler material has a low melting point. The melting point of workpieces should be higher than the filler.

The filler material is heated at the temperature of 800 degrees approximately. It acts as an adhesive between the two pieces. None of the base metal melts. That’s what makes blazing stand out.

Brazing techniques

Brazing can be done in different ways as well. It is decided by the mechanical nature of the metal you are working on. Some of the worldwide used brazing methods are:

- Silver brazing

- Vacuum brazing

- Dip brazing

- Torch brazing

Following are the steps you need to follow if you choose the brazing process:

- Filler material changes according to the nature of the metal. Selecting the right filler material is the first step.

- Metal surfaces to be brazed should be cleaned thoroughly. All the grease and dirt should be removed from the surfaces.

- Use a brush to apply a layer of flux on the surface to avoid oxide formation.

- Then heat is required to meet the melting point of the filler.

- Apply the filler material to the joint section to connect the pieces.

- Clean the metal after brazing as well.

Metals for brazing

Brazing is a very flexible process. Brazing can be done on a wide range of metals. Some of the best brazing metals include copper, steel, aluminum, bronze, stainless steel, etc.

Metal gluing

One of the easiest ways to weld two metals is using glue or adhesive. It is less expensive and gives the strength nearly as strong as blazing.

The main advantage of using glue is that only a little preparation is required. No specialized tool or machinery is needed for this.

To glue two metals together, you need to follow these steps carefully:

- Make sure the working place is free from debris and clutter. Otherwise, small fragments will stick to the joint.

- Your working space should have nice ventilation.

- Clean the joints which are to be glued together. All the dust and grease should be removed for the clean finishing.

- Latex gloves should be worn for protection. This way, your hands will be safe from direct contact with the glue.

Glues for bonding metals

As we need to carefully choose the filler material for brazing, similar is the case with gluing. The type of glue to be used totally depends on the metal’s nature. Some of them are:

- Bondic

- Loctite epoxy

- HG power glue

- Henkel adhesives

- Permatex epoxy

Using bolts and nuts

Another great way to join two metals together is by using bolts and nuts. It is a commonly used method in the automotive industry. This method is very similar to riveting but not the same.

No special machinery is needed for this process. The size of bolts and nuts varies from project to project. The main equipment required here is a drill machine. Leverage and friction are used to secure two metal pieces together.

- First of all, you need to arrange the equipment needed to join the two metals.

- Your working place should be free from clutter.

- Now, drill holes in the metals.

- Through the holes, you need to insert the bolt into the metal.

- Use a nut according to the size of the space and screw it from the opposite side.

That is all you have to do and you will get a nice and clean result without having to do welding. This is an entirely heat-free process. In addition, no special training is required for this technique.

Soldering

Searching for another way to weld without a welder? A method known as soldering is also widely used when it comes to connecting to metals. An electrical iron, propane torch, or gun is required along with a filler material. The filler material is mainly tin or lead.

What is solder?

Solder can be considered as an alloy or a metal in a shape of wire or a stick. It melts when the temperature is low metal and results in binding the metals together.

Flux and filler material is mixed to form solder. Flux helps in cleaning the dust particles and grease from the contact surface.

The solder is heated until it becomes molten. Then it comes in contact with the metals that need to be joined. It acts as a glue that penetrates through the surface and gaps of the metal pieces.

Metals to be used while soldering

Soldering is very effective when it is done for brass, copper, or tin. But when it comes to iron, stainless steel, or aluminum, soldering doesn’t prove to be any useful.

Soldering is an easy process but the main problem of soldering is low strength. Soldering does not give a result as strong as brazing or welding. That is the reason, it is only suitable for small projects which require less strength.

- Metal surfaces should be cleaned with flux.

- Connect the two pieces in the way you want them to be joined.

- Apply a proper amount of solder on the joints.

- Use the electrical iron or gun to melt the filler material.

- Repeat the same process for all the sides.

Riveting

Still, looking for a method to weld two metals without a welder? Riveting is another way to do so. It is an ancient technique that requires rivets and heat to create a strong bond. All around the world, bridges are still constructed using riveting.

One important thing to remember here is that the metals and the rivets should have the same mechanical properties.

It is an easy and low-cost method. This technique is used when high strength is required.

In ancient times, this technique was used before welding. The Eiffel Tower in Paris is built using this technique.

You may encounter some problems while using riveting::

- It is not leak-proof.

- As a result of expansions and contractions during summer and winters, the rivet tends to loosen itself.

- Vibrations can also result in the loosening of rivets. For this reason, they need to be timely replaced.

Best metals for riveting

Copper, brass, aluminum, and stainless steel are some of the best metals that can be used for riveting.

- Metal pieces that are to be joined should be held strongly.

- In both pieces, drill a hole.

- Take a rivet and insert it in the hole.

- A rivet gun can be used to tighten the rivet to join the two metals together

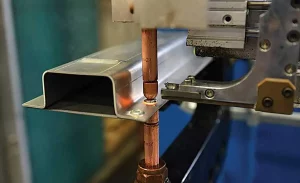

Spot welding

If you are looking for another alternative to joining metals, spot welding might be the best choice for you. As the name appears, no need to confuse whether welding is required or not. Because we are here to discuss welding techniques without a welder.

In the automotive and robotic industry, this is a commonly used technique.

Spot welding is a process in which electric current is used to apply a combination of heat and pressure to the metal. Another term used for spot welding is “resistance spot welding”.

The copper electrodes are used for this process. Metal sheets are brought closer to each other and no filler material is used. Electric current passes through the electrodes towards the metal sheets. And as a result, two metal sheets are converted into one flat piece.

Best metals for spot welding

Some of the metals that are suitable for spot welding are:

- Aluminum

- Copper

- Galvanized steel

- Stainless steel, etc.

- First of all, the electrodes and metal plates should be thoroughly cleaned. They should be free from any dust particles or debris. Because these dust particles can cause sparks which can be dangerous.

- Electrodes and metal sheets are to be aligned correctly to join them together.

- Eyes protection and welding gloves are required for safety purposes.

- When everything is placed in its right position, make contact of electrodes with the metal surfaces which are to be welded together.

- Turn the switch on and hold the assembly for 3-5 seconds.

- Turn it off and remove the metal sheets from the assembly.

- Now both metals are joined together and can be used after cooling.

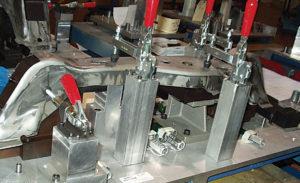

Clamping

Clamping is also a technique when it comes to joining metals. You can widely see its applications in the plumbing system of buildings. They can strongly hold the two metals together and can be removed when needed. One drawback of this process is the cost which is more than the cost of welding.

FAQs

Now, here are a few questions that people ask about this topic. They might come to your mind as well.

- Is there a way to weld without a welding machine? Indeed there is. Riveting, bolting, soldering, clamping, spot welding and brazing, etc are some of the easiest techniques that you can use if you don’t want to use a welding machine. Each technique depends on the nature of the metal you are working on or the nature of your project. Selecting the right method as per your project requirements can make your work a lot more efficient and smooth.

- Can you weld with a torch? Yes. Metals can be welded using a blowtorch. It can be a little tricky as compared to welding. In order to join the two metal pieces together, it requires a large amount of heat and thermal energy. Different welding torches can be used depending upon the metal you are working on. For example, a propane torch can be used to weld some metals such as aluminum.

- Can you DIY weld? Stick Welding can be used for this purpose if you are trying to weld two metals at home. Clean the two surfaces which are to be connected. Heat the filler material and the surfaces to be joined. The stick is melted in the joints which are to be connected to get high strength.

- Is there any simple and economical way to weld? Stick Welding is the easiest and cheapest way to weld. It is pretty simple and basic. The overall equipment is also easy to set whether you are indoors or outdoors. The process is versatile, pretty simple, and less hazardous.

Wrapping up

The above-mentioned non-welding techniques can be used when you want to weld two metals together without a welder. In normal circumstances, traditional welding can be the best option for you. However, if you want to try other methods and explore new options without using much machinery and effort, these methods can be proved beneficial for you.

All the methods we have discussed here have their own pros and cons. So choosing the right method according to the metal you are dealing with is the wise decision. That’s why make sure you have the right equipment and machinery for welding the metal pieces.